The Durability of Engineering Ceramics

When considering materials for advanced applications, the longevity of engineering ceramics stands out as a critical factor. These materials are designed to withstand harsh conditions, high temperatures, and mechanical stress, making them a preferred choice in various industries. Whether in aerospace, biomedical applications, or electronic devices, their resistance to wear and tear is unmatched. This durability translates into reduced maintenance costs and increased equipment reliability, instilling confidence in engineers and manufacturers alike. Choosing engineering ceramics means investing in longevity, which is essential for sustainable development and cost-effectiveness in production. Consider how much more efficiently your projects can operate when they are built to last!

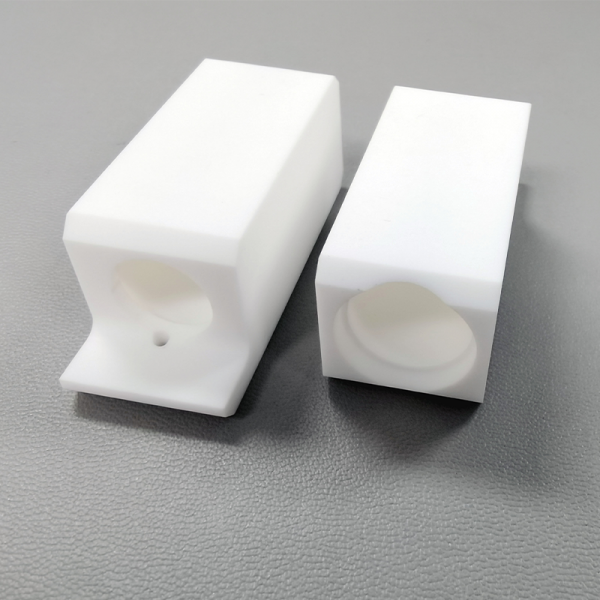

Understanding Engineering Ceramic Materials

The foundation of engineering ceramics lies in their composition, which includes various minerals and oxides. These engineering ceramic materials exhibit unique properties such as high hardness, excellent thermal stability, and chemical inertness. These characteristics allow them to perform exceptionally well in demanding environments, where traditional materials might fail. As technology advances, the exploration of new compositions continues to broaden the potential applications of these materials. By embracing these innovations, industries can enhance their product offerings, ultimately leading to improved performance and efficiency. Therefore, investing in the knowledge and understanding of these materials is critical for engineers seeking to push the boundaries of design and functionality.

The Promise of Engineered Ceramics

Moving beyond traditional materials, engineered ceramics offer tailored solutions for complex applications. These advanced ceramic materials are designed with specific functionalities in mind, allowing for enhanced performance characteristics such as improved toughness or variable porosity. The customization of engineered ceramics opens new doors for innovation in product design, contributing to sectors ranging from electronics to biomedicine. The ability to engineer materials to meet precise requirements not only boosts the performance of devices but also encourages the exploration of new technologies. This versatility empowers engineers to realize their visions and create game-changing products that can redefine standards within their industries.

Summarizing the Key Insights

In summary, the choice of engineering ceramics greatly impacts the performance and longevity of products across various sectors. The durability of these materials, along with their unique properties, positions them as a top choice for modern engineering challenges. With a deep understanding of engineering ceramic materials and advancements in engineered ceramics, manufacturers can develop innovative solutions that stand the test of durability and efficiency. For those seeking reliable supply advantages and unparalleled expertise, look no further than Great Ceramic. Their commitment to quality and innovation ensures you receive the best materials tailored for your project’s success.